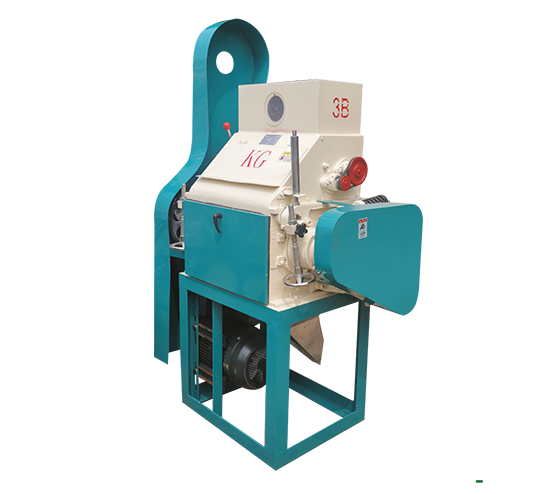

6F Roller Mill

⚙️ Key Features of a 6F Roller Mill

| Feature | Description |

|---|---|

| Rollers | Typically consists of 2–4 pairs of rollers (chilled iron or steel). Each pair grinds the grain finer. |

| Material | Processes wheat, maize (corn), rice, etc. depending on the model. |

| Output | Ranges from 300 kg/h to over 1,000 kg/h, depending on model size. |

| Function | Often integrates grinding, sieving, and grading in one unit. |

| Power | Usually powered by electric motors (5–15 kW). |

TO INQUIRE ABOUT THIS PRODUCT call : +254 715 086 793 OR FILL IN THE FORM BELOW

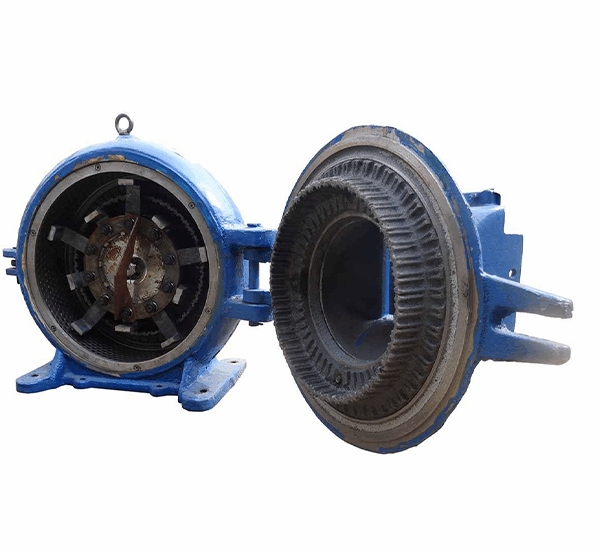

AIRLOCK

In flour milling, an airlock (also known as a rotary airlock valve or rotary feeder) is vital for regulating the flow of flour or grain between areas with different air pressures—usually between a pneumatic conveying system and atmospheric pressure zones. The tightly fitting vanes reduce air leakage, effectively sealing the pressure difference.

This allows material to pass through while preventing air or gas from escaping or entering, which is crucial in pneumatic systems.

Common applications include:

-

Below cyclone separators or bag filters

-

Under silos or bins feeding pneumatic lines

-

Between processing stages that require air pressure isolation

BUCKET ELAVATOR

A bucket elevator is a vital machine in grain and flour milling, designed to vertically lift bulk materials such as grain, flour, or bran between different stages of the milling process. It uses motor-driven belts or chains with attached buckets to transport materials efficiently.

Purpose in Milling:

-

Moves grain, flour, or bran between processing stages (e.g., cleaning to grinding).

-

Optimizes space by transporting materials vertically.

Common Uses:

-

Grain mills – Transporting grain between storage and processing.

-

Flour mills – Moving flour or bran through production and packaging.

-

Feed mills – Elevating feed grains for processing.

| Model | Stocks | Bucket model | Bucket volume (L) | Bucket distance (mm) | Capacity (t/h) | ||

| Speed Ratio | |||||||

| 1:17 | 1:13 | 1:11 | |||||

| HDTD20/11 | Wheat | DS1109 | 0.27 | 150 | 3.45 | 4.47 | 5.2 |

| Flour | DQ1109 | 0.21 | 150 | 1.5 | |||

| HDTD30/13 | Wheat | DS1311 | 0.51 | 180 | 7.0 | 9.0 | 10.7 |

| Flour | DQ1311 | 0.3 | 180 | 2.4 | |||

| HDTD40/18 | Wheat | DS1814 | 1.35 | 200 | 24.0 | 32.0 | 38.0 |

| Flour | DQ1814 | 0.78 | 180 | 9.0 | |||

| HDTD40/23 | Wheat | DS2314 | 1.6 | 200 | 29.0 | 39.0 | 46.0 |

| Flour | DQ2314 | 1.25 | 180 | 14.8 | |||

| HDTD50/28 | Wheat | DS2816 | 3.7 | 220 | 80.0 | 90.0 | 104.0 |

| Flour | DQ2816 | 1.38 | 200 | 14.7 | |||

| HDTD60/34 | Wheat | DS3321 | 5.81 | 250 | 134 | ||

| Flour | DQ3321 | 3.7 | 250 | 30 | |||

Dehuller

Dehuller – Efficient Grain Husking for Cleaner, Higher-Quality Output

Remove husks and outer shells with ease using our powerful Dehuller, designed to gently yet effectively separate grains like rice, maize, and millet. This machine improves milling yield, enhances grain appearance, and prepares your product for further processing.

✅ High husking efficiency with minimal grain breakage

✅ Suitable for multiple grains including rice, maize, millet

✅ Easy to operate and maintain

✅ Ideal for small to medium-scale milling operations

Unlock the full potential of your grains with the reliable Dehuller.

TO INQUIRE ABOUT THIS PRODUCT call : +254 715 086 793 OR FILL IN THE FORM BELOWDisk mill

The Disk Mill is your go-to machine for efficient grinding of grains, spices, and other materials into fine powders. Featuring robust disk-shaped grinding plates, it delivers uniform particle size, high throughput, and easy operation—perfect for flour mills, feed plants, and spice processing.

✅ Efficient, uniform grinding

✅ Durable construction for long service life

✅ Adjustable fineness for versatile use

✅ Simple maintenance and operation

Gravity stoner

MAGNETIC SEPARATOR

A magnetic separator is a device that removes ferrous (iron-containing) contaminants from materials by applying a magnetic field. In maize and wheat milling, it is essential for maintaining product purity and safeguarding milling equipment.

It usually includes:

-

Strong permanent magnets or electromagnets

-

A housing or chute through which the grain passes

As the grain flows through, iron particles are attracted to the magnet and separated from the clean grain.

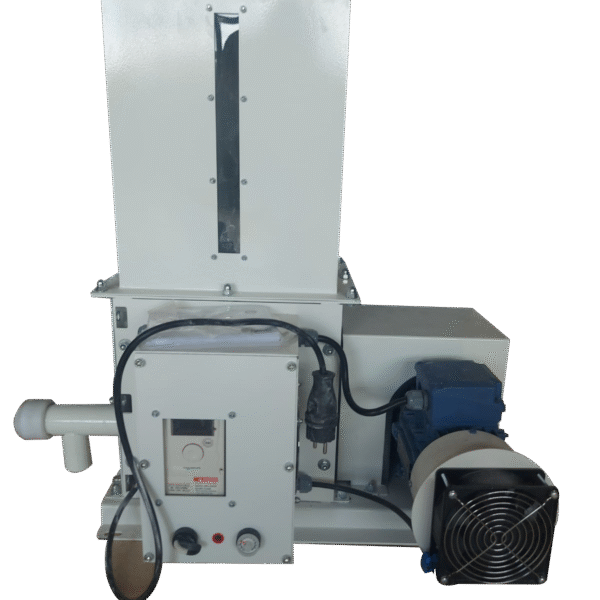

TO INQUIRE ABOUT THIS PRODUCT call : +254 715 086 793 OR FILL IN THE FORM BELOWMicro Doser

Micro Doser – Precision Feeding for Perfect Formulation

Achieve consistent product quality with the Micro Doser – the ideal solution for adding vitamins, minerals, enzymes, or other micro-ingredients with pinpoint accuracy. Engineered for precise dosing and continuous operation, it's essential for flour mills, feed plants, and food processing units demanding high accuracy and efficiency.

✅ Accurate micro-ingredient dosing

✅ Enhances product quality and consistency

✅ Easy integration into production lines

✅ Low maintenance, high reliability

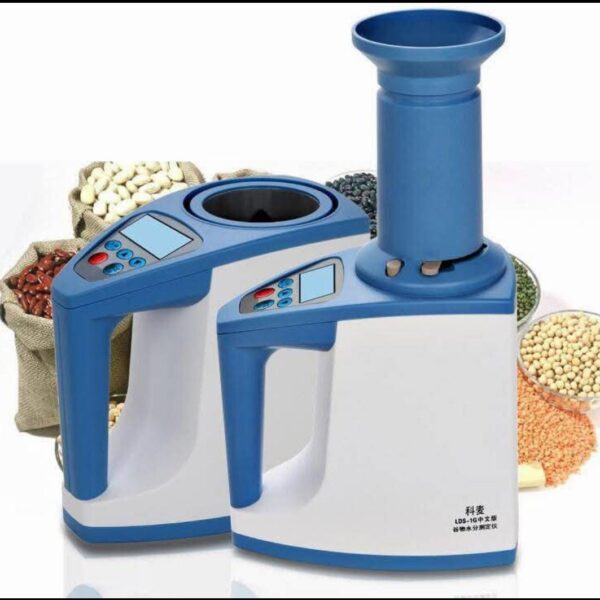

Moisture Meter

Moisture Meter – Accurate Moisture Testing Anytime, Anywhere

Ensure optimal quality and storage conditions with our Moisture Meter—a fast, reliable tool to measure moisture content in grains, flour, and other materials. Easy to use and highly accurate, it helps prevent spoilage, improve processing, and maintain product standards.

✅ Quick and precise moisture readings

✅ Portable and user-friendly design

✅ Suitable for grains, flour, and seeds

✅ Essential for quality control and storage management

Moisture Meter white

Moisture Measure – Fast & Reliable Moisture Detection

Get accurate moisture readings instantly with our advanced Moisture Measure tool. Designed for farmers, millers, and processors, it ensures your grains and products stay within optimal moisture levels to maximize quality and shelf life.

✅ Rapid, precise moisture measurement

✅ Easy to operate, portable design

✅ Ideal for grains, seeds, and powders

✅ Helps prevent mold, spoilage, and quality loss

Multicleaner

SCREW CONVEYOR

- Helical screw blade (also called a "flight") mounted on a shaft

- Tube or trough that houses the screw

- Drive mechanism (motor and gearbox)

- Inlet and outlet ports for loading and unloading material