6F Roller Mill

⚙️ Key Features of a 6F Roller Mill

| Feature | Description |

|---|---|

| Rollers | Typically consists of 2–4 pairs of rollers (chilled iron or steel). Each pair grinds the grain finer. |

| Material | Processes wheat, maize (corn), rice, etc. depending on the model. |

| Output | Ranges from 300 kg/h to over 1,000 kg/h, depending on model size. |

| Function | Often integrates grinding, sieving, and grading in one unit. |

| Power | Usually powered by electric motors (5–15 kW). |

TO INQUIRE ABOUT THIS PRODUCT call : +254 715 086 793 OR FILL IN THE FORM BELOW

COLOUR SORTER

A color sorter, also known as an optical sorter, is a machine commonly used in grain and food processing industries to automatically detect and remove defective items or foreign materials by identifying differences in color.

In grain milling—such as maize, wheat, rice, and other cereals—color sorters are used to:

-

Eliminate discolored or spoiled grains

-

Remove foreign seeds and contaminants like stones, plastic, string, metal, moldy kernels, etc.

-

Enhance both the visual appeal and hygiene quality of the final product

DAMPER

HIGH EFFICIENCY VIBRATING SIEVE

IMPURITY SUCTION SEPARATOR

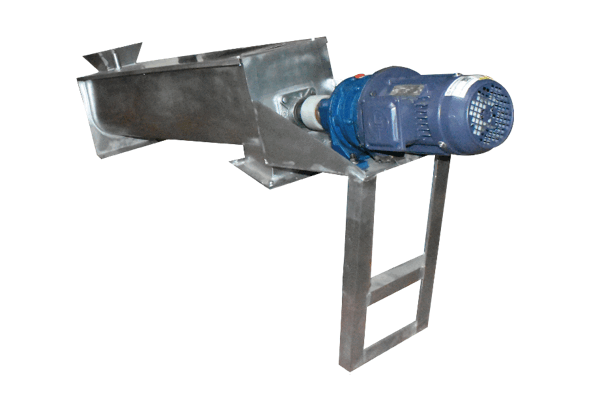

MAGNETIC SEPARATOR

A magnetic separator is a device that removes ferrous (iron-containing) contaminants from materials by applying a magnetic field. In maize and wheat milling, it is essential for maintaining product purity and safeguarding milling equipment.

It usually includes:

-

Strong permanent magnets or electromagnets

-

A housing or chute through which the grain passes

As the grain flows through, iron particles are attracted to the magnet and separated from the clean grain.

TO INQUIRE ABOUT THIS PRODUCT call : +254 715 086 793 OR FILL IN THE FORM BELOWMaize Degerminator for Wheat/maize Flour Milling Machine

PNEUMATIC ROLLER MILL

PURIFER

| Model | Sieve width (cm) | Air volume (m3/min) | Sieve layers | Sections | Capacity(kg/h) | Air volume (m3/h) | Power(kw) | Weight(kg) | Dimension (mm) |

| HQFQ 49×3×2 | 490*2 | 40-70 | 3 | 2 | Coarse granule:2800 Fine granule: 800 | 2400-4200 | 0.18×2 | 970 | 2732×1290×1700 |

| HQFQ 59×3×2 | 590*2 | 50-80 | 3 | 2 | Coarse granule: 3300 Fine granule: 960 | 3000-4800 | 0.18×2 | 1200 | 2732×1490×1754 |

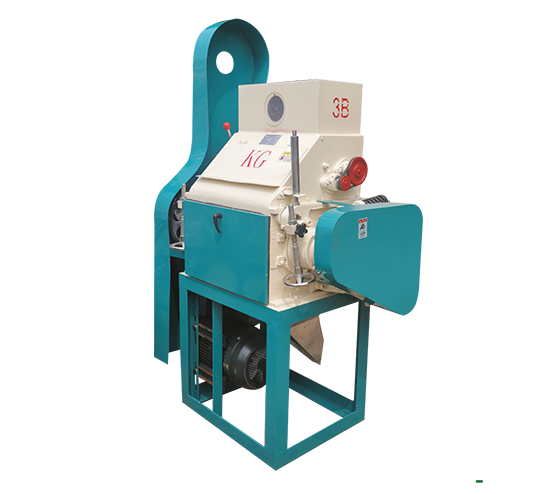

REFLUTING MACHINE

A fluting machine is a specialized tool used in flour mills to re-groove or re-sharpen the rolls (cylinders) in roller mills. These rolls are essential for grinding maize, wheat, and other grains into flour. Over time, the grooved (fluted) surfaces of the rolls wear out and must be restored to maintain optimal milling performance.

Purpose and Benefits of a Fluting Machine:

-

Cuts or re-cuts grooves (flutes) into steel or cast-iron rolls used in grain milling

-

Ensures rolls retain their cutting precision, grip, and efficiency

-

Restores the grinding effectiveness of worn rolls

-

Helps maintain consistent flour quality

-

Extends the lifespan of rolls and minimizes operational downtime

Rice Grader

Rice Grader – Precision Sorting for Premium Quality

Ensure consistent rice quality with the Rice Grader – your solution for accurate separation by size and uniformity. Designed to sort broken, small, and whole grains efficiently, this machine enhances the overall value of your final product and meets the highest market standards.

✅ Accurate grading by size and shape

✅ Improves product quality and market value

✅ High throughput with low power usage

✅ Suitable for all rice varieties

Rice machine

Unlock the full potential of your rice production with our advanced Rice Machine – engineered for efficiency, durability, and top-quality output. Whether you're hulling, polishing, or grading, this all-in-one solution delivers clean, uniform rice with minimal breakage and maximum yield.

✅ Efficient husk removal and polishing

✅ Low breakage, high yield

✅ Easy to operate and maintain

✅ Suitable for small to large-scale operations